|

Plug specifications: 120 Volt; 20+ Amp; 2-pole; 3-wire; grounding; twist-lock Example: Hubbell HBL2311 plug

When installing a plug:

Making an Extension Cord:

Generator Instructions:

Plug specifications:

When installing a plug:

Making an Extension Cord:

Generator Instructions:

Plug specifications:

When installing a plug:

Making an Extension Cord:

Generator Instructions:

Plug specifications:

When installing a plug:

Making an Extension Cord:

Generator Instructions:

Plug specifications:

When installing a plug:

Making an Extension Cord:

Generator Instructions:

Cleaning the welding shoe of an extrusion welder is an important step when stopping work for the day or any extended period of time.

When installing a plug on to a power cord:

Ensure your tool is completely cooled down before shutting off:

Watch for a plugged air intake:

If a tool's heater tube gets wet:

Changing the element on a VARIMAT

Correct the nozzle position on a VARIMAT Working with generators

The two hold-down assemblies and the green belt in the picture below keep the top layer of membrane flat on the bottom layer as it is heated by the nozzle, just before the drive tire presses down on it.

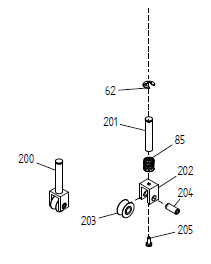

Each hold-down assembly contains the following parts:

If your Variant T1 stops driving while welding, check that the heater locks correctly into the welding position.

How the Weld Position Locking Mechanism Works

After allowing the tool to cool down completely. Slide the heater all the way to the right/outside of the tool. Note that you can now see a groove in the guide shaft.

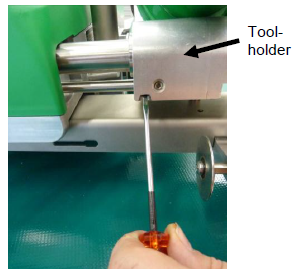

In the picture below, a small flat screw driver is being held against a ball bearing set screw. |

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policy |

|

Proud Member of: