|

If your Variant T1 stops driving while welding, check that the heater locks correctly into the welding position.

How the Weld Position Locking Mechanism Works

After allowing the tool to cool down completely. Slide the heater all the way to the right/outside of the tool. Note that you can now see a groove in the guide shaft.

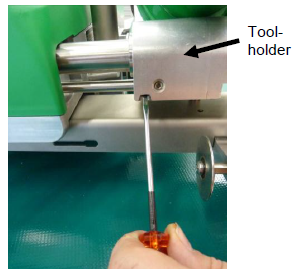

In the picture below, a small flat screw driver is being held against a ball bearing set screw.

The spring-loaded ball bearing at the end of the set screw fits into the groove in the guide shaft and holds the heater in the weld position. When the user pushes the heater out of the weld position, the ball bearing is pushed back against the spring and out of the groove, so that the heater can move along the guide shaft.

If the ball bearing set screw is too loose, the heater can slide out of weld position while welding, which stops the drive. If the ball bearing set screw is too tight, the heater cannot move along the guide shaft. How to Set the Weld Position Locking Mechanism

Still having problems? We offer repair services by factory trained technicians. Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policy |

|

Proud Member of: