|

The well-known Austrian commercial firm Haberkorn Ulmer has had a new building erected in Leonding. The highly complex architectural structure is the first industrial firm in a newly established enterprise zone. It comprises an office section with a training and seminar area as well as a warehouse. The office facility is constructed with an ultra-low-energy design. It has hydronic radiant floor heating supplied with groundwater, ceiling cooling, permanent ventilation, daylight-controlled lighting and above-average insulation. This means it fulfills the "Minergie" standard. Click image to enlarge. Confidence in tools and roofers

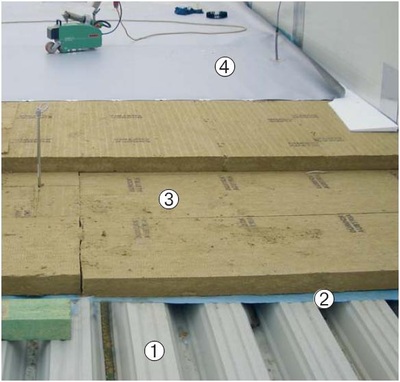

The two building sections are crowned by a 4,500 square meter flat roof. As a Leister sales partner, Haberkorn Ulmer did not hesitate selecting a company closely familiar with Leister tools to construct the flat roof. The preferred roofing contractor was Reifetshammer. The company, hailing from Wels, Austria is considered to be one of the country‘s most important roofing companies, laying over 250,000 square meters of roof area each year. There are 65 people employed in the head office alone. Reifetshammer has many years of experience working with Leister tools. Besides numerous TRIAC hot air tools, the new automatic hot air welder, VARIMAT V2, also is used by this specialty roofing company. Positive feedback For Haberkorn Ulmer, it was something quite special to witness this important Leister tool in use on its own roof and hear testimonials regarding how well it performed. The maximum working speed of the VARIMAT V2 is twice that of its predecessor at 12 meters per minute. Welding of the geomembranes took place last winter, sometimes in harsh conditions, thus a maximum welding speed of four meters per minute was required. At the same time, the hot air unit ensured a heat output of 500 degrees C. Welding was even possible in zones close to edges and around the domed roof lights. Mr. Kuba, the roofer, was particularly pleased with the work he had done: "I’ve been working with the VARIMAT V2 for the first time here. It was very comfortable to work with after a brief familiarization phase. The VARIMAT V2 welds quickly and keeps precisely on course. The processing quality during overlap welding is tremendous. It’s easy to set the welding parameters with the new "e-Drive" operating unit, and the large display can be read clearly. As a user, I’m also pleased that Leister has placed great importance on ergonomics during the development. The VARIMAT V2 can be controlled easily using the adjustable guide handle. Above all, it welds tightly with absolute reliability. I would not hesitate to recommend this automatic hot-air welder." When it came to complex details such as draw welding at the fastening rails of the boarding, Reifetshammer utilized the proven and reliable hand tool, the TRIAC S. Training as a factor of success Only trained and certified Leister sales partners can pass their knowledge on to their customers. Therefore, Leister provides its sales and service partners with state-of-the-art training rooms at its head office in Switerland. Experts from around the world are familiarized with new products to high-level of expertise training here, whereas new employees of the sales partners receive intensive basic training. Thanks to these permanent training and refresher course offerings, Leister can guarantee that the expertise and knowledge gained by the sales and service partners is passed on to the end-user. In this way, the high quality of the tools is also reflected in the results. Besides high quality and international availability, the transfer of expertise is one of the key factors behind Leister's success. Knowledge transfer is paramount Trained Leister sales and service partners provide users with expertise in their own training rooms throughout the world. A good example of this is the company Haberkorn Ulmer. This innovative commercial company has taken advantage of a new building to establish a state-of-the art training room. Here you will find a complete range of Leister products for welding plastic. Not only will you find tools for roofing applications, but also those for other areas such as civil engineering, flooring, apparatus construction, tarpaulin manufacturing or industrial hot air applications. During the first quarter of 2011 alone, 26 training sessions were held with a total of 150 participants from all over Austria. Therefore, the investment has more than paid off for Haberkorn Ulmer. Building: Haberkorn Ulmer GmbH, Austria, www.haberkorn.com Architects: Poppe und Prehal GU: ARGE Alpine Swietelsky, Austria, www.swietelsky.at Building owner: Haberkorn Ulmer GmbH Roofers: Reifetshammer, Austria, www.reifetshammer.at Welding equipment: Leister Technologies AG, Switzerland, www.leister.com Leister Sales & Service partners: Haberkorn Ulmer GmbH Text: Christophe von Arx, Leister Technologies AG Fotos: Roland Beeler, Leister Technologies AG Erwin Pal, Haberkorn Ulmer GmbH Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policy |

|

Proud Member of: