|

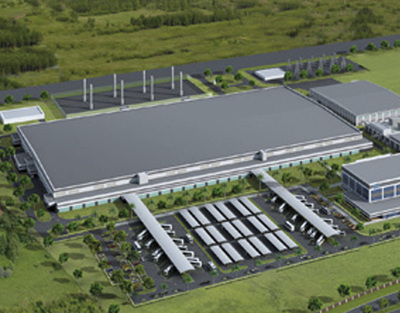

Vietnam is an up-and-coming country. Above all, the comparatively low wages are among the important attractions for foreign companies. 60 % of the population is under 30, which means the potential labour force is correspondingly large. Moreover, this "Asian Tiger" also offers investors a very good tax environment. The domestic market itself is also becoming increasingly lucrative. All these are valid reasons that make Vietnam appealing as a production location. Click image to enlarge. Gigantic flat roof

It will therefore come as no surprise that Intel singled out Ho Chi Minh City as a location for an enormous production plant. The world's largest manufacturer of semiconductors has been expanding its production facilities massively here for around 300 million US$. Welding machines made by Leister were used in the construction of one of the buildings. The gigantic flat roof measures 40,000 m2. Carlisle recommends Leister Intel had specified the use of the plastic sheet seal ENERGY STAR of Carlisle in the tender. This TPO material reflects the heat from the sun's rays and therefore helps to save valuable energy for cooling the building. In its specifications, Carlisle recommended welding the overlapping welds with devices made by Leister. Leister has an authorized sales partner on-site in Vietnam – as it does in 90 other countries as well. In this case the partner is Dong Loi Equipment & Service Co. Ltd. This was the very first opportunity for the Vietnamese enterprise, AIM ProTech, to work with equipment made by Leister. The employees of AIM ProTech were trained in the VARIMAT V and also supported on the roof by Dong Loi. Those laying the sheeting were highly impressed with the handling and weld quality of the VARIMAT V after completing the work. Requirements more than fulfilled In East Asian countries as well, the power supply on construction sites is often provided by a generator. The resultant voltage fluctuations create problems for many electrical devices. Not so for the VARIMAT V: Fluctuations are compensated for thanks to its electronic control. The fabricator was therefore able to achieve a continuously high level of welding efficiency. Extreme conditions outside The high air humidity of over 90 % and an average temperature of up to 35° C place great demands on man and machine at every building site here. The VARIMAT V coped with these outside conditions brilliantly as well. There were no problems whatsoever during the entire laying period. A feat all the more remarkable as the welding machine was permanently in use. The fastest roof welding machine in the world 1000 m2 plastic sealing sheets had to be processed each day. The VARIMAT V welds at up to 5 m/min. That makes it the fastest welding machine in the world. After just 40 days the work was completed to the satisfaction of everyone. The weld seam quality is perfect. In order to exert as little pressure on the weld seam as possible, work was carried out on this thin plastic roof sheeting without extra weight. Once again, the patented pendulum roller has proven its merits here. It evens out side unevenness, therefore ensuring the greatest possible process reliability. High quality requirements Whoever believes no value has been placed on quality in this construction project is clearly mistaken: As the building owner, Intel specified that the American ASTM standard be complied with. As a result, Intel inspectors examined welds for their tightness on a daily basis. Thanks to the reproducible welding parameters (pressure, speed, temperature) of the VARIMAT V, the weld quality could be maintained at all times. Cool and secure The giant building has meanwhile been completed. Around 1200 Intel employees now work here. They can enjoy the benefit of a constant climate inside and rest assured that they are working under a completely watertight roof – welded with the VARIMAT V welding machine from Leister. Building owner: Intel Plastic sealing sheets: TPO ENERGY STAR von Carlisle Plastic welding devices: Leister Process Technologies Laying out company: AIM ProTech Sales and service partner: Dong Loi Equipment & Service Text: Christophe von Arx, Roland Beeler, Leister Process Technologies Photos: Dong Loi/Peter Kathriner, Leister Process Technologies Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policy |

|

Proud Member of: