GEOSTAR G5/G7 Wedge Welder |

|

|

|

|

The GEOSTAR wedge welder is the fastest Leister wedge welder available with a top welding speed of 12 m/min, depending on conditions. Its lightweight, cast aluminum frame and ergonomic handle make it easy to carry and position. It features a unique digital display that shows key welding parameters. The new design makes field servicing and cleaning easy and allows the wedge to be changed quickly. Available in two performance classes: the standard GEOSTAR G5 and extended-wedge GEOSTAR G7.

- Welding speed of up to 12 m/min, depending on conditions

- 20-50% lighter than comparable machines

- Digital display shows weld pressure, speed, and temperature

- Quick wedge replacement even in the field

- Adjustable ground clearance

- Easy access to mechanical parts for cleaning or service

- Two-gear transmission allows changes to drive speed range

- Consistent pressure regardless of terrain

- Materials:

- GEOSTAR G5: HD-PE 0.8 - 3.0 mm, PP, LD-PE, TPO, FPO, PVC-P*2, CSPE*2, EIA*2

- GEOSTAR G7: HD-PE 1.0 – 3.0 mm, PP, LD-PE, TPO, FPO

*2: Requires stainless steel wedge

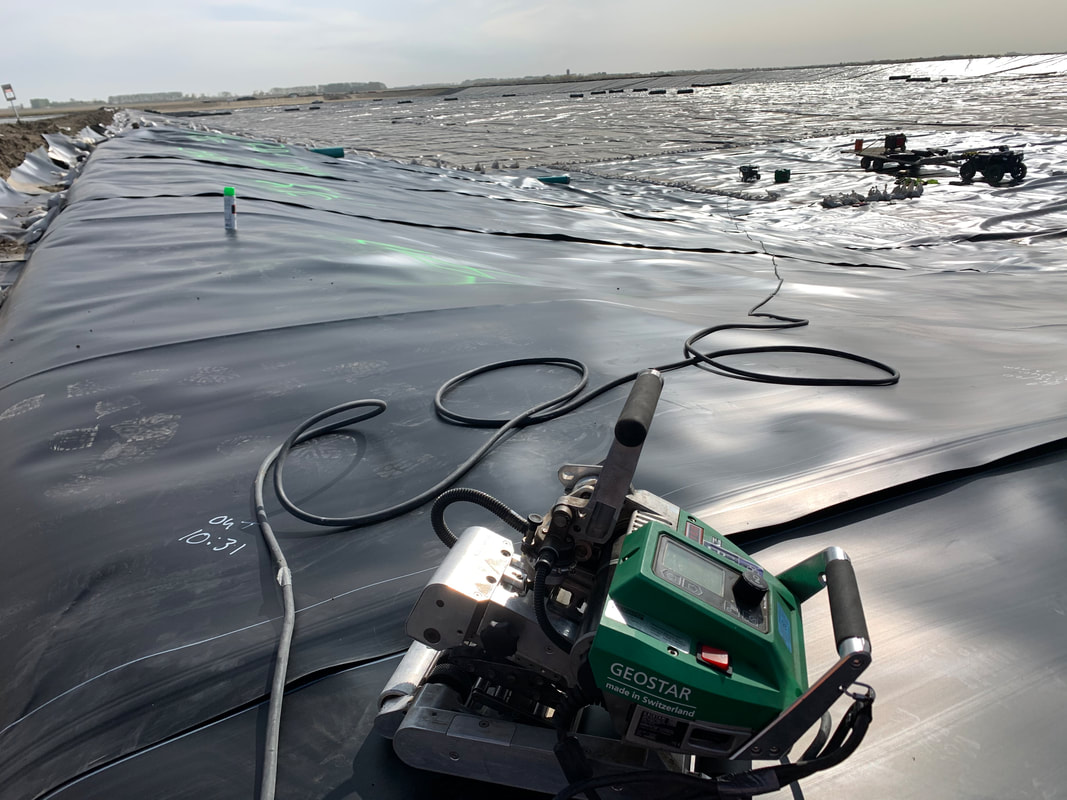

Customer TestimonialA Leister Geostar G7 was recently used by Engineered Pipe Group for the relining of this 147,000 m² wastewater lagoon in White City, Saskatchewan using 60mil smooth HDPE membrane. Andrew Doyle of Engineered Pipe Group specifically remarked on the Geostar’s “ease of loading and wedge set up.” The Geostar is available with LQS, giving operators and QA/QC the ability to track the machine’s speed, temperature, clamping force, and GPS coordinates for each weld. This data helps ensure the welding parameters are consistent throughout the job, keeping the welds in the sweet spot of the welding triangle, and the simple cloud-based storage of the machine’s data allows stakeholders to reference specific weld data whenever needed. |

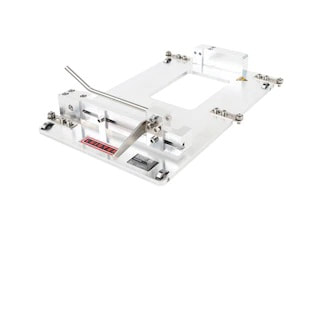

GEOSTAR G5 / G7 LQS - Leister Quality System

|

|

The Leister Quality System (LQS) allows you to compile full quality documentation for all aspects of your welding work. You can document every welding seam as a table, graphic or even with GPS coordinates. The GEOSTAR G7 / G5 LQS provides all the advantages of state-of-the-art technology. It really stands out from the crowd - helping you to win over your client.

GEOSTAR G7 / G5 LQS

|

Why Buy From Us

The GEOSTAR is available in Canada only through STANMECH and its distributor network. Tools bought through us are electrically certified for use in Canada. In many cases this entails replacing cords or switches in the tool to meet stringent CSA standards. Each tool is physically inspected by an approved field inspector prior to certification. We offer same-day shipping on in-stock items from our facility in Burlington, Ontario, Canada.

Technical Data

|

|

GEOSTAR G5 |

GEOSTAR G7 |

Voltage |

V |

230 |

230 |

Power consumption |

W |

2800 |

2800 |

Max. Temperature |

ºC |

460 |

460 |

Welding wedge |

mm |

90 x 50 |

130 x 50 |

Max. overlap |

mm |

150 |

150 |

Max. welding force |

N |

1500 |

1500 |

Weld width |

mm |

2 x 15 |

2 x 15 |

Drive speed*1 |

m/min |

0.8 - 12 |

0.8 - 12 |

Dimensions |

mm |

482 x 278 x 269 |

482 x 278 x 269 |

Weight |

kg |

16.4 |

17.7 |

Approval markings |

|

CE, QPS |

CE, QPS |

Electrical protection |

|

Class II |

Class II |

1: Conversion of gear 1– 2 using position change of sprocket wheels |

|||

Part Numbers

151.035: GEOSTAR G7, 230V/2800W, Roller width 50 mm, copper wedge with test channel, without plug

151.683: GEOSTAR G5, 230V/2800W, Roller width 50 mm, copper wedge with test channel, without plug

155.152: GEOSTAR G7 LQS data recording, 230V/2800W, copper wedge with test channel, without plug

156.135: GEOSTAR G5 LQS data recording, 230V/2800W, copper wedge with test channel, without plug

151.683: GEOSTAR G5, 230V/2800W, Roller width 50 mm, copper wedge with test channel, without plug

155.152: GEOSTAR G7 LQS data recording, 230V/2800W, copper wedge with test channel, without plug

156.135: GEOSTAR G5 LQS data recording, 230V/2800W, copper wedge with test channel, without plug